|

|

|

|

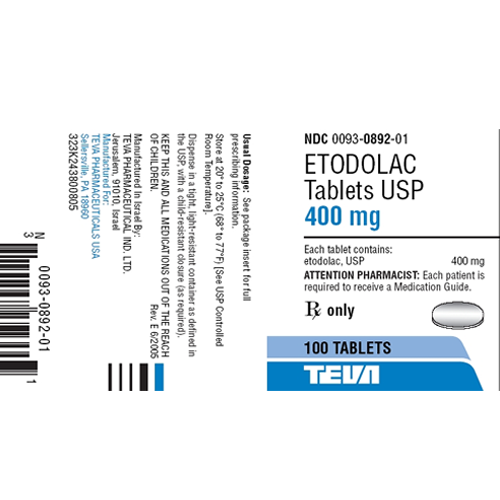

Before the era of barcodes, safety inspections and quality checks were recorded by hand often in a ledger or log book. This type of record-keeping is not always accurate, especially when dealing with hundreds of thousands of items. What is more, human error is natural and always a factor in this type of situation.

In manufacturing industries, resources or raw materials go through dozens of checks and inspections to ensure their stability and quality. These tests are recorded for verification purposes, allowing inspectors to monitor the status and consistency of specific batches. By simply scanning the barcode after each phase of testing, quality assurance monitors have an accurate record of all materials or products at all times.

However, printing barcodes goes further than just quality assurance, especially in some of manufacturing industrials could be highly regulated, highly volatile industries in which the risks of an incident can be quite high if proper precautions aren ot taken. Barcodes can actually ensure the safety of employees, and can be created to allow and deny access to potentially dangerous jobsites, creating a safe barrier for those who might unknowingly try to enter. By equipping certified employees with special barcodes that react with sensory doors and elevators, maximum safety can be achieved. Barcodes provide a solution to monitoring and tracking these resources, taking the guesswork out of potentially dangerous situations.

Barcodes are making an impact on manufacturing industries every day. By creating tracking solutions for materials and helping to identify potential hazards in the workplace, it is more and more common for organizations to generate barcodes in order to achieve integral standards for safety.