|

|

|

|

Keeping track of products throughout the entire distribution process is essential to controlling costs, managing inventory and ensuring the quick and reliable delivery of goods. Businesses with sound logistical processes ultimately benefit in the form of an improved bottom line and more satisfied customers.

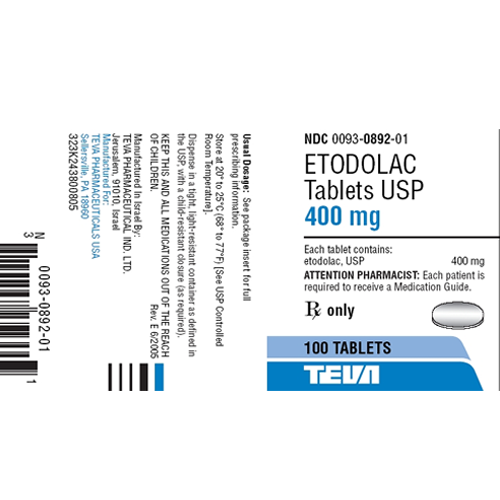

Barcoding is one of the most efficient ways to manage products as they move along the supply chain, as they can store serial numbers, lot numbers, handling information and almost any other information you require as your product moves through the channel. Relying on manual tracking is unreliable and results in higher error in product tracking, especially when you consider the broad availability of affordable and dependable barcoding solutions.

Barcoded labels, printers and scanners can greatly expedite the process of getting a product to its end user by giving you a great deal of insight to the critical information you need in real time.

In the warehouse, cross docking, yard management and pick-up and delivery operations can be made more efficient, saving you money and freeing up manpower. Improved inventory management means your company will spend less time looking for lost products and equipment, and will have better operational efficiencies.

Access to updated information also impacts shipping capabilities, allowing you to better plan for load and route requirements, to address any problems in the shipping process and to communicate more effectively with dispatchers and drivers. Dock workers can benefit from improved inventory information as well, and barcoding helps mitigate any potential shipping handling errors.